Softwood Plywood

Made from the finest Western softwoods.

ENGINEERED TO YOUR SPECIFIC NEEDS.

We have a longstanding reputation for manufacturing the highest-quality commodity and specialty softwood plywood. We can provide the right grade, the right finish, and the right specs for your needs.

Not only do we meet performance requirements, we also meet the toughest environmental requirements.

Applications

Barracuda

BarracudaPly is a marine panel line in our softwood plywood collection. Our marine panels are industrial and commercial grade with high quality faces and backs. They are certified by the APA – The Engineered Wood Association and available as FSC certified.

GRADES

BarracudaPly is available in three different grades: BarracudaPly Marine Grade – BarracudaPly Marine Guard – BarracudaPly BB

CERTIFICATIONS

APA – The Engineered Wood Association – Available as FSC certified

APPLICATIONS

Boat Building – Pontoon Boat Flooring – Docks – Boat Houses/Buildings – Shelving – Storage or Garage Cabinets – Flooring for Ambulances, Buses, and RVs – Outdoor Signs

Siding

Available lengths: 8’

Available thicknesses: 11/32” and 19/32”

Specie: Douglas Fir

Applications: Siding for sheds, apartments, townhomes, condos

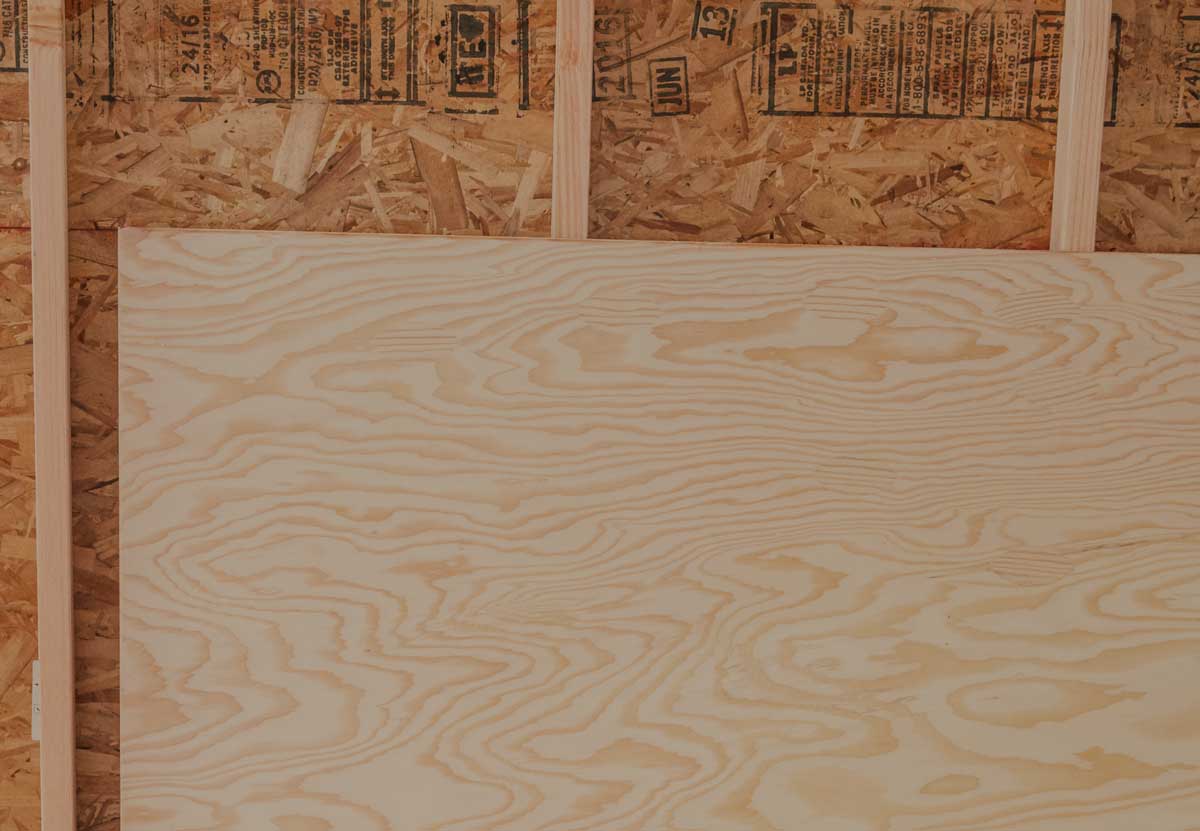

Sheathing

Sheathing is applied to the outer studs, joists, and rafters of a building to strengthen the structure and is meant to shed water and protect the walls from the effects of weather.

Grades: CDX, CDX Struc I, CCX and Rim Board

Underlayment

Underlayment is typically used under flooring or roofing where added insulation and structural integrity is required.

Grades: C X-band, Tongue & Groove

Custom Cuts

Our sanders and specialty glues allow us to fabricate panels for a wide range of performance requirements. We can even engineer panels to meet the unique and specific needs of individual customers— including panels up to 5′ wide, 10′ long and 1-1/8” thick. We also offer plug and-touch sanding, full sanding and tongue-and-groove.

How and where it’s made

GRANTS PASS, OR | MEDFORD, OR

Our plywood plants in Grants Pass and Medford use state-of-the-art technology to manufacture our softwood plywood with the greatest possible efficiency. Best of all, as a fully integrated company, we control production, costs, and quality from start to finish.