FalconPly™ Hardwood Plywood

Strength Meets Craftsmanship – Real Wood. Premium Hardwood Plywood for Every Application.

Manufacturing Quality Hardwood Plywood Products

Our FalconPly™ hardwood plywood is built for strength, consistency and sustainability. Each panel is crafted with hand-selected real wood veneers for premium quality and precision.

Available in multiple core options, it meets North America’s highest environmental standards, including CARB Phase 2 and TSCA Title VI Certified, with additional FSC® Chain-of-Custody certified upon request.

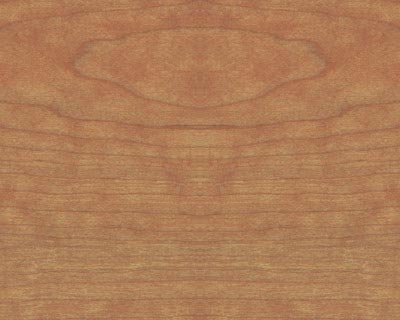

VENEER CUTS & MATCHING OPTIONS

Our hardwood plywood is crafted with real wood veneers, selected for rich character, consistency and premium quality. We offer over 200 veneer species, including maple, oak, birch and responsibly sourced exotics.

For architectural projects, veneers are hand-selected for color consistency and can be sequence-matched across panels. We offer a range of veneer cut styles – including rotary, quarter-sliced, rift-cut and plain-sliced – to achieve the desired grain pattern and visual effect.

…and many more available species.

Hardwood Plywood Core Options & Performance Summary

FalconPly™ hardwood plywood is available in multiple core types, each engineered for specific performance needs. Below is a comparison of key attributes.

Softwood Veneer Core

Key Benefits

Consistent thickness, excellent laminating surface

Best For

Cabinetry, furniture

Hardwood Veneer Core

Key Benefits

Excellent stability, lightweight, with consistent performance

Best For

Architectural panels, furniture

Tropical Veneer Core

Key Benefits

Higher density, smooth finish, excellent dimensional stability and durability

Best For

Furniture, cabinetry, interior paneling

Pro-Core

Key Benefits

Combines veneer core strength with MDF smoothness

Best For

High-end furniture, paneling

Particleboard Core

Key Benefits

Cost-effective, smooth laminating surface

Best For

Commercial interiors, fixtures

MEDIUM-DENSITY FIBERBOARD CORE

Key Benefits

Extremely smooth surface, great for laminates

Best For

Millwork, furniture

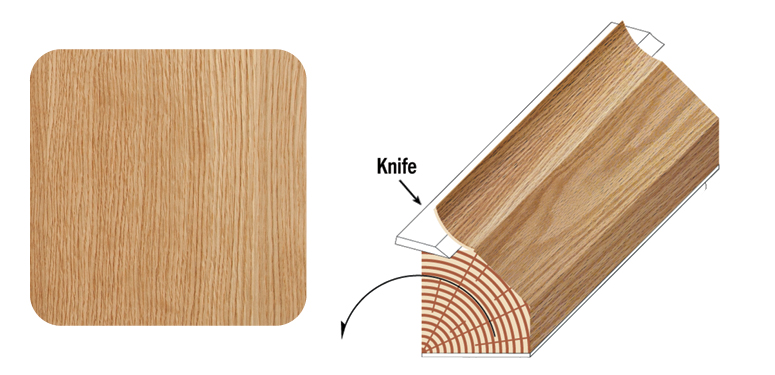

VENEER CUTS

A hardwood’s grain is responsible for its unmistakable beauty and appeal. Timber Products uses four unique processes to produce a range of wood patterns that are graded and sorted by hand, ensuring a reliable grain pattern on each and every panel.

Choose from a variety of cut styles and matching techniques to achieve your desired grain pattern and visual effect.

Rotary Cut

The log is centered in the lathe and turned against a knife blade at a slight angle following the log’s annular growth rings, producing a multi-patterned grain veneer.

Quarter Slicing

Produces a narrow, striped grain veneer where the growth rings of the log strike the blade at approximately right angles.

Rift Cut

Produces a rift or comb grain effect similar to that of quarter slicing, but generally is only used with red and white oak. Minimizes ray flake as the log is cut at an angle of about 15 percent off the quartered position.

Plain Slice

The most common slicing method that produces a distinct cathedral grain veneer. A half log, or flitch, is mounted so that the veneer is cut along the growth rings, parallel to a line through the center of the log.

Veneer Matching

Our Munising, Michigan veneer facility produces exceptional maple and hardwood veneers with strict attention to detail and quality. Advanced splicing and pressing technology allow us to offer an expanded range of options for spliced veneer applications.

Pleasing Match

Veneer sheets are carefully selected and arranged to create a visually appealing pattern.

Book Match

Veneer cut from the same log are arranged side by side in a way that creates a mirrored or symmetrical pattern.

Slip Match

Consecutive sheets of veneer are laid side by side in the same orientation, creating a uniform and consistent pattern.

Plank Match

The sheets of veneer are arranged without following a specific sequence or grain alignment. This method creates a more natural and varied appearance.

Whole Piece

Whole piece veneers are cut from a single section of the log, ensuring uniformity and a seamless, continuous grain pattern.

Compliance & Sourcing Assurance

Sourcing you can trust

In addition to our domestic mills, Timber Products operates an import division and maintains strong vendor relationships – allowing us to stock a wide range of veneer species in various cuts and grades.

Our dedicated compliance team goes beyond industry standards to ensure that all materials are ethically sourced and legally verified. This added layer of oversight protects our customers and promotes responsible forest management across the entire supply chain.

Frequently Asked Questions

What is hardwood plywood?

Hardwood plywood is an engineered wood panel made by layering real hardwood veneers over a core for strength, durability and dimensional stability. It offers the beauty of natural wood while maximizing the utility of every tree harvested.

The outermost layer – called the face veneer – features visually appealing species like maple, oak or cherry. The core is built with stronger, more utilitarian woods that provide structure and long-term durability. This combination makes hardwood plywood a sustainable, resource-efficient solution for furniture, cabinetry and architectural interiors.

FalconPly™ is Timber Products’ premium hardwood plywood brand. Crafted in the U.S. using hand-selected veneers and precision manufacturing, it meets the highest standards for quality, consistency and environmental compliance.

What core options are available for FalconPly™ hardwood plywood?

FalconPly™ hardwood plywood comes in a range of engineered core types, each optimized for specific performance needs:

- Softwood Veneer Core (White Fir & Douglas Fir): Consistent in thickness, second to none laminating surface

- Hardwood Veneer Core (Southern Poplar): Lightweight with excellent dimensional stability and consistent performance

- Tropical Veneer Core (Fuma): High density, strong, smooth finish with excellent stability

- Pro-Core: Combines the strength of veneer core with a smooth MDF face for optimal performance

- Particleboard Core: Cost-effective with a smooth laminating surface

- MDF Core: Smooth, hard and consistent laminating surface that can be machined without chipping

What makes FalconPly™ different from other hardwood plywood products?

- Precision manufacturing in dedicated U.S. facilities

- Hand-selected veneers for consistent grain and color matching

- Advanced adhesive technology for durability & low emissions

- Industry-leading quality control at every stage of production

- Certified for CARB Phase 2, TSCA Title VI, FSC® and CANFER compliant

How do I choose the right hardwood plywood for my application?

Selecting the right hardwood plywood depends on performance needs, application and finish requirements. Key considerations include:

- Structural vs. decorative use – Veneer core for strength, MDF for smooth finishing

- Screw holding & machinability – Veneer cores offer superior fastener retention

- Weight vs. density – Tropical and Veneer Cores are lighter-weight options compared to MDF, Particleboard and Pro-Core

- Environmental conditions – CARB-compliant, FSC-certified options available

- Surface finish compatibility – MDF and particleboard cores provide the best laminating surfaces

What veneer matching options are available?

We offer multiple veneer matching techniques to achieve precise visual consistency:

- Pleasing Match – Prioritizes an aesthetically harmonious design

- Book Match – Creates a mirrored or symmetrical pattern

- Slip Match – Veneer are laid side-by-side in the same orientation, creating a uniform and consistent pattern

- Plank Match – A more natural appearance, mimicking the irregular patterns found in solid wood

- Whole Piece – Veneers are cut from a single section of the log, ensuring uniformity and a seamless, continuous grain pattern

How do you ensure consistent quality across manufacturing facilities?

Our rigorous quality control process ensures uniformity and durability across all FalconPly™ panels:

- Hand-selected veneers graded by experienced professionals to ensure consistent color, grain and quality across every panel

- Multiple inspection points throughout production

- Testing for mechanical properties (MOR, MOE, Janka hardness and screw hold strength)

- Standardized manufacturing across all facilities

- Third-party certification for emissions and environmental compliance

How does FalconPly™ support sustainability?

Timber Products is committed to sustainable forestry and responsible manufacturing. FalconPly™ is:

- Manufactured using responsibly sourced wood species

- Compliant with CARB Phase 2, TSCA Title VI and CANFER emissions standards

- FSC® Chain-of-Custody certified upon request

Timber Products also maintains an import division and trusted vendor network to support a broader range of responsibly sourced veneer species. Our in-house compliance team actively monitors the supply chain to ensure legality, sustainability and peace of mind for our customers.

What technical support and resources are available?

We provide comprehensive support, including:

- Custom solutions for unique applications

- Installation and finishing recommendations

- On-site consultation and product training

- Samples and mockups upon request

Contact our plywood specialists to discuss your specific requirements or request samples.